I like building things, exploring caves, playing folk music,and The Exploratorium. I'm working as an engineer at Joby Aviation.

Most of my time at Otherlab was spent engineering and building a prototype solar car. Our goal was to exploit the efficiency gains found in small, low-speed vehicles to create a disabled access urban vehicle which could go days without requiring a recharge.

I briefly worked with the Everfly team to help build a prototype tethered electric helicopter intended for use as a fixed radio antenna.

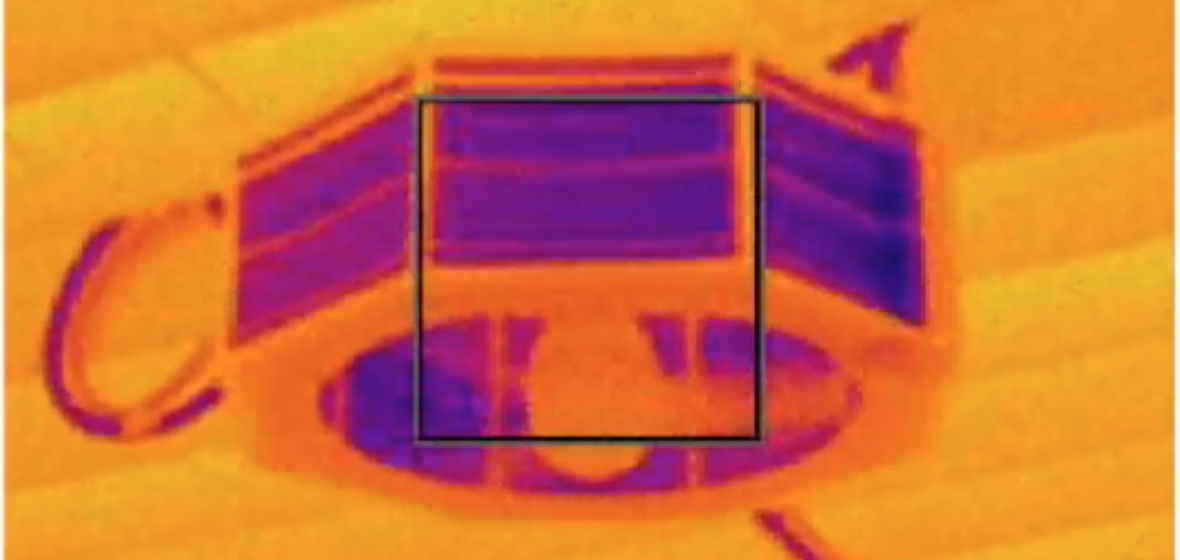

I spent some time testing some new designs for heat exchangers, using thin plastic films as the separator medium. Pictured is an IR image of one our prototypes in action.

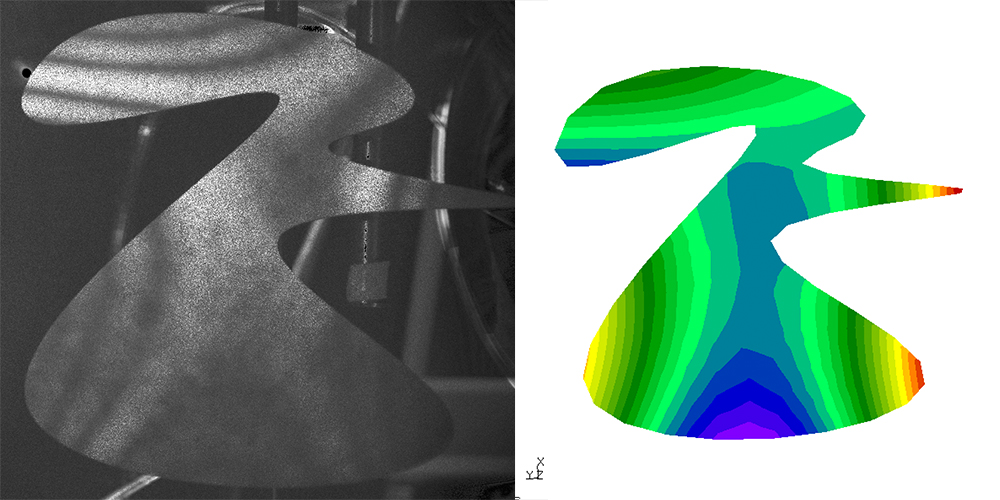

For my senior thesis at Reed College I designed, built, and tested the performance of various designs of plate bells. The bells were designed by simulating their vibration and then optimizing the boundary shapes to create the desired sounds. The bells were then cut out of aluminum plate using a water jet cutter. Using this technique I was able to create the bell pictured left, which matches the frequency profile of a church bell to a very high precision. If you're interested in how I did it the code is on my Github, and you can check out my seminar presentation or an article about my thesis as well.

The left panel of this animation shows the development of the outer contour of the bell as its sound approaches the target. The green line in the right panel shows the target frequencies of overtones, and the blue line the set generated by the bell.

In order to verify that the bells were vibrating as intended, I built an Electronic Speckle Pattern Interferometer, which gives a visual representation of the vibration of an object. The large white areas in the left-hand image represent the regions of least vibration, while the fringes indicate areas of deformation. The right-hand image shows the nodes produced by the simulation.

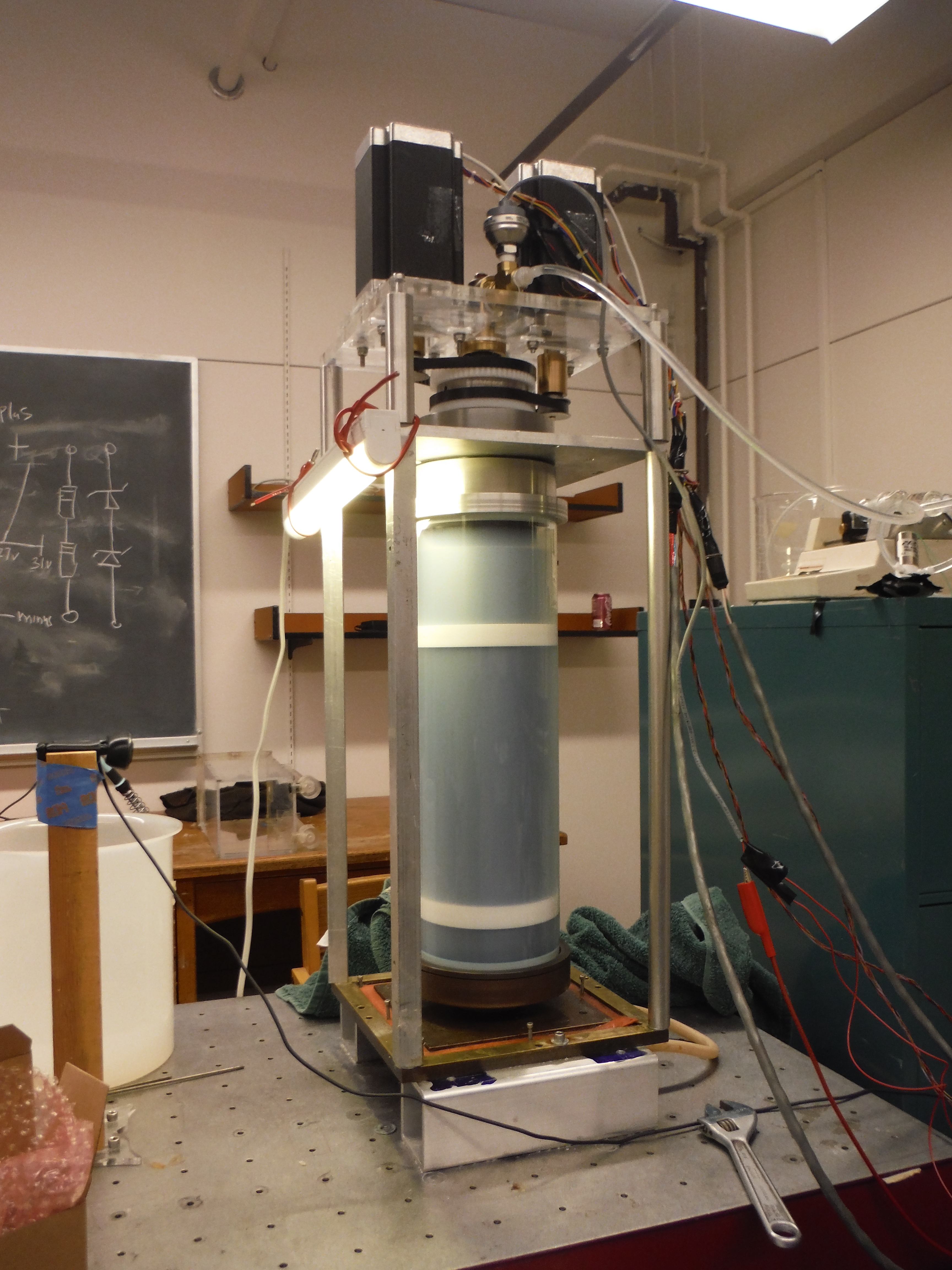

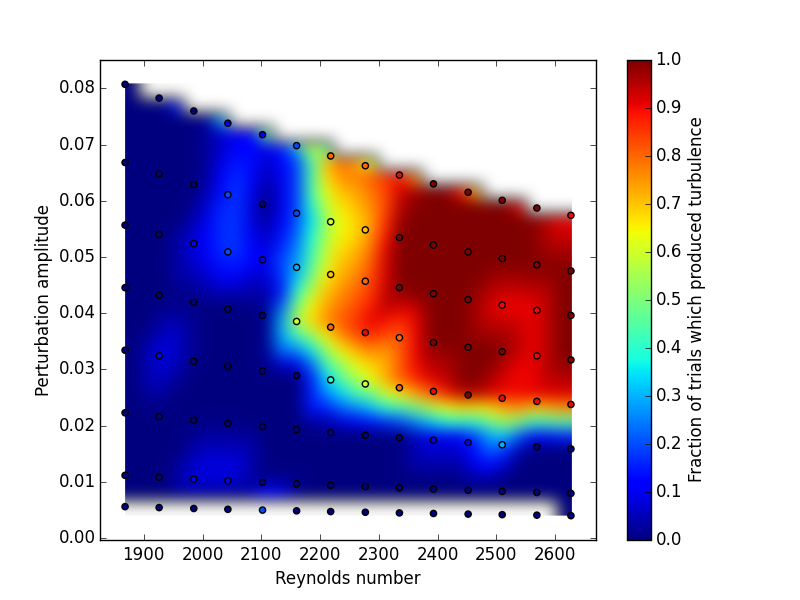

The object of study in my research was Taylor-Couette flow, a type of flow found in fluid held between two rotating cylinders. Such flows can exhibit chaotic behavior, and thus require large amounts of data to adequately describe. In order to collect this data, I designed a system that used stepper motors to drive the inner and outer cylinders independently. A webcam then imaged the resulting flows, and image analysis code using OpenCV and written in Python extracted data. The entire process, including stall recovery and flow relaminarization, was automatically managed by a Raspberry Pi. Using this setup, we were able to find the trend we were looking for!

A plot of the results of the study. The red areas indicate parameters of flow which lead to a turbulent state. The fact that there is a well-resolved boundary, and that it follows an inverse polynomial curve, confirmed our experimental hypothesis. You can see a short seminar presentation I gave on this research for more details.

Laser cutters are great! Here's a heart I made from wood, paper, and acrylic. There's 13 layers of paper to give the inside a 3D effect.

Laser cut, design drawn up in Inkscape.

You put your thumb through the middle when you're reading a book and it holds the pages open for you! Also laser cut and designed in Inkscape.

Made of thick steel wire, welded, and sanded. Later converted to LED fans (not pictured).

Made of recycled upholstery material, denim, and backpack liner.

Rings made from wrapped steel wire. Gold and Nickel plated using a homemade electroplating rig.

My first attempt at Schlieren photography, an imaging method through which you can see the density of air in a small area. It works by bouncing a collimated light source off a parabolic mirror, then placing a sharp obstruction (like a razor or piece of foil) in the focus to subtract out most of the light. Any light which was refracted by changes in air density misses the obstruction, so the camera picks up these deviations as bright spots in the image.

Rideable things made from scavenged parts

A see-saw pushcart - the seesawing action turns a cam which propels the cart forward. The hardest part of this build was getting tough enough bearings - I tried bike bottom brackets, but with hundreds of pounds of force on them the axles would just shear off.

Swinging along the bars on the rotating drum power the wheels forward. This project worked just fine, but it turns out it takes ridiculous amounts of upper body strength to propel it anywhere. Check out the article my college wrote about it.

A diabolically long and tall bike. It needs an entire intersection to turn.

My favorite bike by far. This one's so tall that you have to get on it by leaning it against a lamppost and climbing up it. It'a actually way safer than the long bike.

Not an original idea, but fun. By putting PVC shims on the rear wheels, you can drift this thing down hills.

The front and rear wheels of this bike turn independently, so you can ride it sideways! Original concept thanks to the awesome Peter Wagner of Whymcycles.

It's like a tandem, but sideways!

This is actually rideable.

Your submission has been received!

Oops! Something went wrong while submitting the form :(